- content admin

- Articles

Tech Tip 2: Why You Should Transport, Manage, and Use Your PI AF Hierarchy in the Cloud

When managing complex industrial operations, data is your most powerful asset—but only if it’s structured, accessible, and contextualized. If you’re using the PI System with Asset Framework (AF), you already know the power of organizing your operational data into a well-structured hierarchy. But what happens when you move that hierarchy into the cloud?

Bringing your PI AF hierarchy into the cloud isn’t just about modernization. It’s about unlocking the full potential of your operational data to improve efficiency, collaboration, and business outcomes.

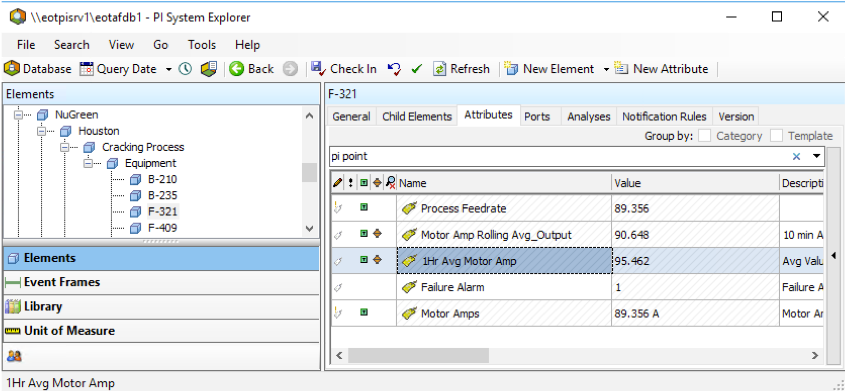

What is PI AF Asset Models and Hierarchy?

PI Asset Framework (AF) allows organizations to structure operational data into hierarchical models that reflect the real-world relationships between industrial assets. Instead of just collecting raw sensor data, AF Hierarchies provide:

- A contextual model: Organizing data based on sites, equipment, production lines, or asset classes.

- Attributes & metadata: Defining physical properties, operational parameters, and sensor readings associated with each asset.

- Templates for standardization: Ensuring consistency and scalability across multiple locations.

Key Concepts of PI AF Structure:

- Element Templates: Reusable models for standardizing asset definitions.

- Attributes: Properties like temperature, pressure, and runtime linked to live PI tag data.

- Hierarchy Navigation: Parent-child relationships defining how assets are related within an organization.

Example: A Power Plant AF Hierarchy might look like this:

Power Plant ├── Turbine 1 │ ├── Temperature Sensor │ ├── Vibration Sensor ├── Boiler 1 │ ├── Steam Pressure Sensor │ ├── Flow Rate Sensor

This structure allows engineers, data scientists, and operators to navigate and analyze data within their PI System efficiently.

Why Cloud-Based Hierarchies Matter

- Improved Data Organization and Context

By moving your AF hierarchy to the cloud, you retain the intuitive structure that mirrors your plant or asset model while making it universally accessible. Now, both local and remote teams can easily navigate a familiar, standardized model without being bogged down by technical details.

You’re not just pushing data to the cloud—you’re giving your teams a shared map of your operations, layered with rich context and metadata.

- Enhanced Data Analysis

Cloud-hosted hierarchies and graphs enable you to layer advanced analytics, AI, and machine learning directly on top of your organized data. This means faster identification of inefficiencies, deeper insight into asset performance, and the ability to proactively manage operations from anywhere.

- Simplified and Scalable Access

In the cloud, your hierarchy becomes the front door to operational intelligence. Operators, engineers, analysts, and decision-makers can all access the same structured data from different interfaces—dashboards, mobile apps, or custom tools—without lengthy data-wrangling.

As your operations grow, cloud-hosted hierarchies are far easier to maintain and scale, avoiding the headaches of expanding on-premises data models.

- Standardization Across the Enterprise

Cloud-based hierarchies make it simple to enforce consistency across teams, plants, and regions. By creating templates and standard asset definitions in AF and syncing them to the cloud, your teams speak the same language—making collaboration faster and more effective.

- Supports Predictive Maintenance and Real-Time Insights

With your AF structure feeding cloud analytics and AI models, you can automate anomaly detection, predict equipment failures, and optimize maintenance schedules. Your organization moves from reactive to proactive, saving millions in avoided downtime.

- Facilitates Multi-Disciplinary Collaboration

When your operational hierarchy is in the cloud, it’s no longer siloed. Operations teams, data scientists, business analysts, and leadership can all access the same data set, contextualized for their unique needs. Whether it’s a plant operator viewing equipment metrics or a CFO reviewing production trends, everyone is on the same page.

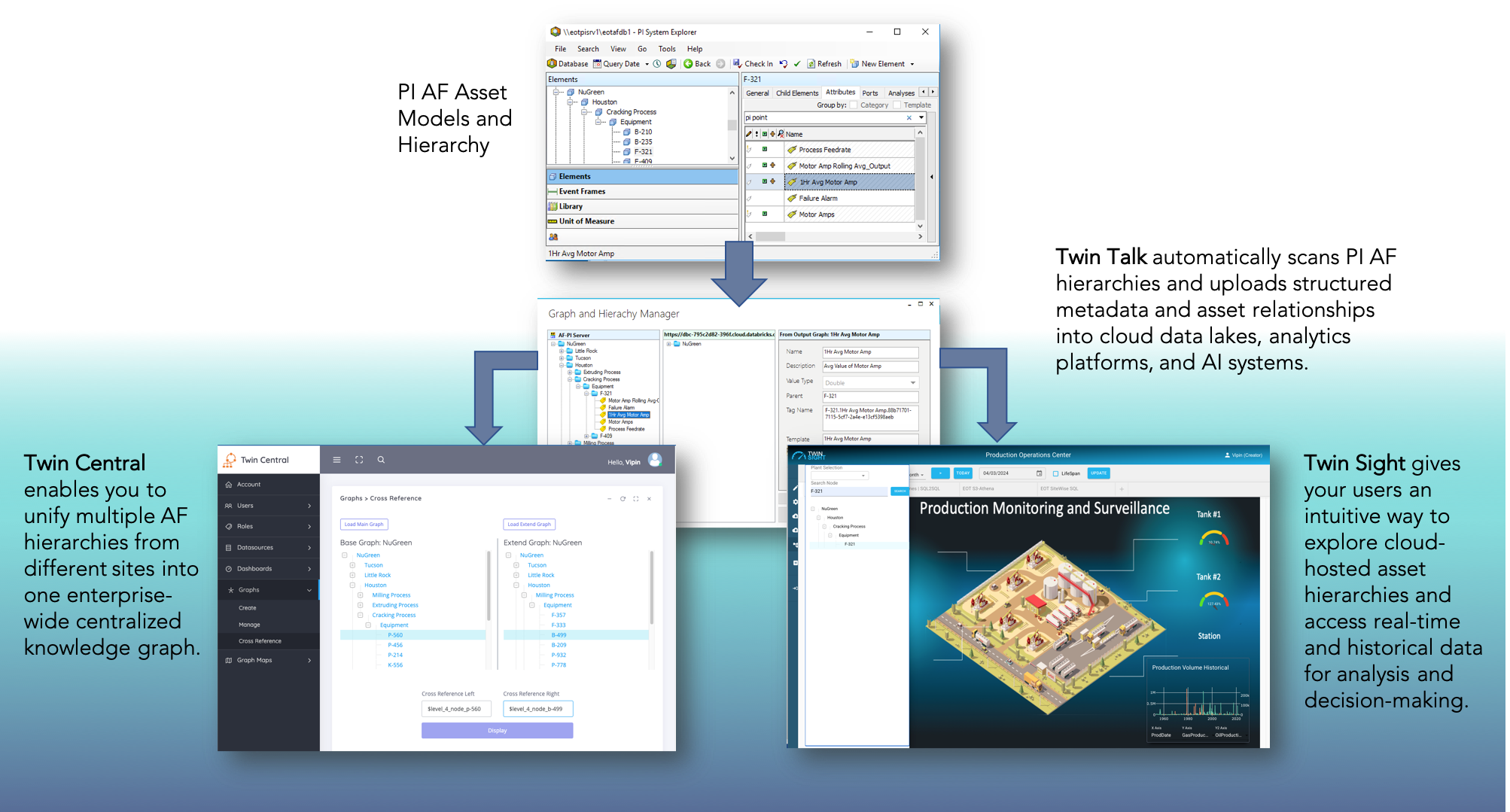

How EOT’s Twin Fusion Product Suite Makes It Happen

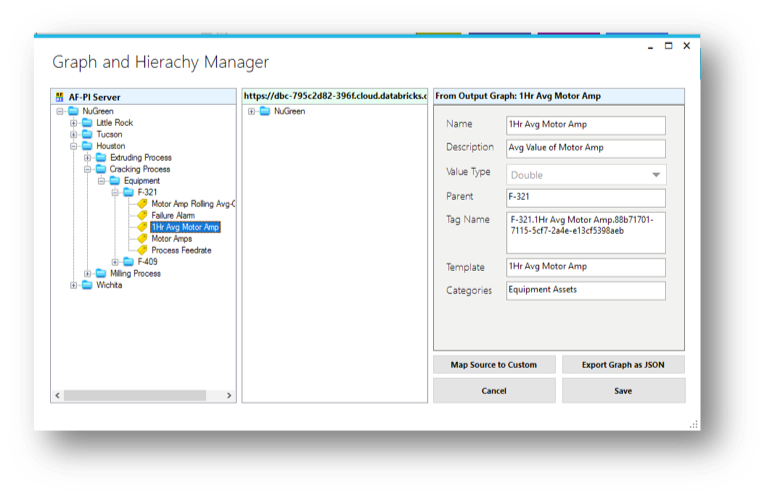

1) Twin Talk AF Scanner automatically scans PI AF hierarchies and uploads structured metadata and asset relationships into cloud data lakes, analytics platforms, and AI systems.

- Scans PI AF structures and extracts element names, attributes, and metadata.

- Supports hybrid environments, allowing cloud and on-premise applications to access real-time AF data.

- Works with Snowflake, Databricks, AWS, and Azure, ensuring data accessibility for AI/ML applications.

2) Twin Central Hierarchy Manager enables you to unify multiple hierarchies from different sites into one enterprise-wide centralized knowledge graph.

- Aggregates multiple PI AF hierarchies from different plants, business units, or subsidiaries.

- Creates a scalable cloud-based asset model that standardizes attributes, templates, and asset relationships across all operations.

- Improves data governance and data lineage tracking, providing a single source of truth for enterprise-wide operational intelligence.

3) Twin Sight Hierarchy Navigation gives your users an intuitive way to explore cloud-hosted asset hierarchies and access real-time and historical data for analysis and decision-making.

- Operators can browse assets, select specific machines, and instantly retrieve associated metadata, sensor data, and historical trends.

- Data scientists can use API-driven access to pull AF metadata for machine learning and predictive analytics.

- IT & business users can explore standardized asset models for enterprise-wide reporting, compliance, and forecasting.

By bridging your OT and IT ecosystems, EOT’s Twin Fusion Suite allows you to fully leverage your asset models in the cloud, unlocking actionable insights and accelerating your digital transformation journey.

How this Helps to Modernize Industrial Enterprises

Moving PI AF hierarchies to the cloud opens the door to advanced analytics, AI, and enterprise-wide operational intelligence.

- Unlock AI-powered Predictive Maintenance

- Enable Cloud-Based Asset Performance Optimization

- Integrate OT (Operational Technology) with IT Systems Seamlessly

By leveraging Twin Talk & Twin Central, organizations can extend the value of their existing PI AF investments, ensuring that operational intelligence is not locked in on-prem but available enterprise-wide.

Want to learn more? Contact us to see how Twin Fusion is transforming industrial operations!

Enterprise Industrial Platform

Why an enterprise industrial platform beats siloed tools — and unlocks aifor operations Point solutions that pull directly from historians or SCADA solve one problem

Reimagining industrial intelligence: How cloud historians can disrupt the automation landscape

EOT.AI’s “Twin Fusion” redefines industrial data handling – merging AI, cloud-native scalability, and real-time intelligence.

Learn how this disruptive approach changes the automation game.

Using ChatGPT to Build an IIoT Anomaly Detection Model and Export to ONNX for TwinSight

In this article, we’ll walk through how to use ChatGPT to create a Python program that: Loads and processes IIoT time series data, Trains an anomaly detection model to detect overheating, Converts the trained model to ONNX format,

Prepares it for deployment using TwinSight Machine Learning Workbench

Beyond data: What ‘Integrated Information Theory’ can teach us about AI and Digital Twins

Discover how Integrated Information Theory [IIT] reshapes the future of AI and Digital Twins.

Learn why connecting and integrating data is the key to building intelligent, adaptive operations.

From data silos to real-time twins – Why 2025 is the year of operational AI

AI isn’t just a trend – it’s transforming how industrial leaders harness their data.

Here’s how EOT.AI helps teams scale innovation from the shop floor to the cloud.

Reflections from AVEVA World 2025 – EOT.AI at the frontier of industrial AI

Explore EOT.AI’s key takeaways from AVEVA World 2025 in San Francisco.

Learn how industrial AI, digital twins, edge computing, and generative AI are shaping the future of data-driven operations.

Enterprise Industrial Platform

Why an enterprise industrial platform beats siloed tools — and unlocks aifor operations Point solutions that pull directly from historians or SCADA solve one problem

Reimagining industrial intelligence: How cloud historians can disrupt the automation landscape

EOT.AI’s “Twin Fusion” redefines industrial data handling – merging AI, cloud-native scalability, and real-time intelligence.

Learn how this disruptive approach changes the automation game.

Using ChatGPT to Build an IIoT Anomaly Detection Model and Export to ONNX for TwinSight

In this article, we’ll walk through how to use ChatGPT to create a Python program that: Loads and processes IIoT time series data, Trains an anomaly detection model to detect overheating, Converts the trained model to ONNX format,

Prepares it for deployment using TwinSight Machine Learning Workbench

Beyond data: What ‘Integrated Information Theory’ can teach us about AI and Digital Twins

Discover how Integrated Information Theory [IIT] reshapes the future of AI and Digital Twins.

Learn why connecting and integrating data is the key to building intelligent, adaptive operations.

From data silos to real-time twins – Why 2025 is the year of operational AI

AI isn’t just a trend – it’s transforming how industrial leaders harness their data.

Here’s how EOT.AI helps teams scale innovation from the shop floor to the cloud.

Reflections from AVEVA World 2025 – EOT.AI at the frontier of industrial AI

Explore EOT.AI’s key takeaways from AVEVA World 2025 in San Francisco.

Learn how industrial AI, digital twins, edge computing, and generative AI are shaping the future of data-driven operations.