into Enterprise Innovation

design intelligent solutions on OT systems that scale effortlessly on IT platforms

and Enterprise Scalability

design intelligent solutions on OT systems that scale effortlessly on IT platforms

Without Limits

design intelligent solutions on OT systems that scale effortlessly on IT platforms

Why Twin Fusion is Different

Twin Fusion isn’t just a platform; it’s a bridge that transforms operational complexity into enterprise-wide innovation. Unlike proprietary, locked-in systems, Twin Fusion’s modular approach empowers OT teams to innovate on their terms, ensuring scalable, actionable solutions that align with business strategy.

Twin Fusion is the only platform that empowers OT teams to create innovations for both operational and enterprise-wide use. By enabling OT teams to design solutions on OT systems that scale effortlessly to IT platforms, Twin Fusion transforms operational complexity into actionable insights, driving cost savings, improved efficiency, and enterprise-wide collaboration.

Twin Fusion enables operational and business users to monitor and optimize industrial Assets

Watch how EOT’s Twin Fusion product suite works together to monitor and optimize industrial assets.

Twin Fusion Enables AI-Optimized Industrial Plants

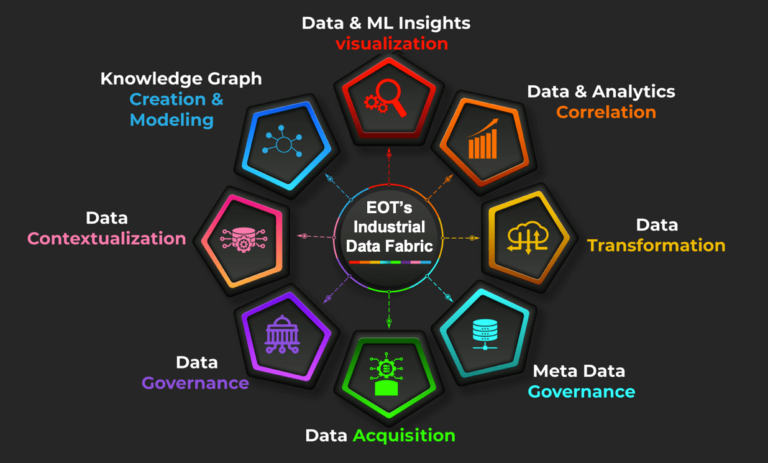

EOT’s Twin Fusions allows you to modernize your industrial OT and IT infrastructure with no tech debt, on an enterprise-scale level and out-of-the-box. It simplifies architecture which delivers rapid results. EOT’s Industrial Data Fabric enables:

- Operational analytics, ML and visualization with Twin Sight

- Semantic enterprise asset data interconnection and modeling with Twin Central

- Operational data ingestion, curation and contextualization with Twin Talk.Twin

Unlock the Promise of AI-Optimized Industrial Plants

If you want to optimize each individual industrial asset, if you want to capitalize enterprise wide cost savings, efficiency boosts, and production surges by applying expansive analytics and machine learning, then you are facing significant challenges. Where to start? How to start? How to save a failing project? Below you’ll find case studies, best practices, and solution blueprints.

Unleash the Power of AI

Use AI Optimization

TwinFusion provides overarching enterprise insights while zooming into individual asset nuances.

Unique Technology

Don’t be just reactive. With Twin Fusion’s patented technology you can foresee issues and optimize before they escalate.

Designed for Rapid Piloting

Validate digital transformation projects in days (not months) by easily and quickly publishing operational data to the cloud. With no work-arounds, hacks or custom integrations.

Trust and Access Control

Federated identity and access management system designed specifically for operational systems. Fully decentralized and distributed with built-in redundancy and guaranteed uptime.

Future-Proof Your Investment

Deploy on any cloud infrastructure, platform or application. Our solution is designed to be open and vendor neutral.

Customizable Modules

Every industry and use case is unique, and so can be your approach to each one.

Twin Fusion is enabling OT and business users to create a unified data model of industrial assets

Watch how embracing AI-enhanced active unified data model curation and utilizing semantic graph modeling to facilitate OT/IT/ET data contextualization and discovery.

Manufacturing Industry

The Manufacturing Industry can significantly benefit from utilizing Twin Fusion, analytics, and machine learning for operational data from their industrial assets to save costs and increase revenue with Predictive maintenance, Production optimization, Quality Control and Assurance, or Supply Chain Optimization.

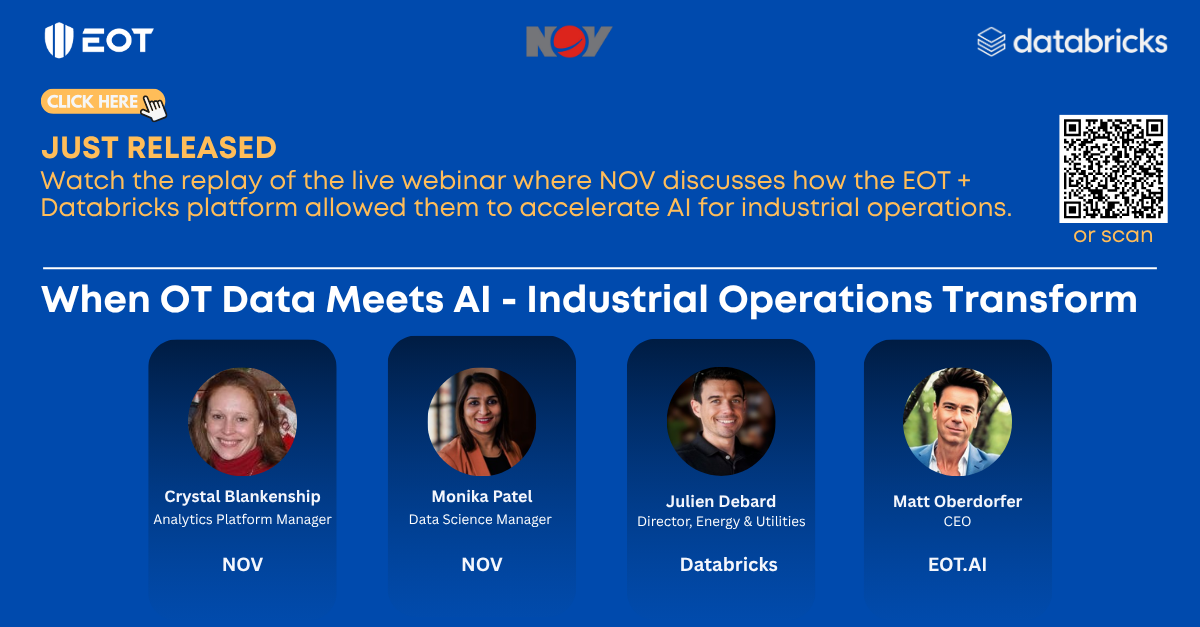

Oil & Gas Industry

The Oil & Gas Industry can significantly benefit from using analytics, AI, and machine learning for operational data from their industrial assets to save costs and increase revenue with Predictive maintenance, Drilling Optimization, Reservoir Characterization and Simulation, or Production Optimization.

Energy Industry

The Energy Industry can significantly benefit from using analytics, AI, and machine learning for operational data from their industrial assets to save costs and increase revenue with Predictive Maintenance, Energy Demand Forecasting, Renewable Energy Optimization, or Grid Management and Stability.

Mining Industry

The Mining Industry can significantly benefit from using analytics, AI, and machine learning for operational data from their industrial assets to save costs and increase revenue with Predictive Maintenance, Mine Planning and Optimization, or Mineral Exploration and Targeting.

BPX Energy Case Study

Learn how BPX Energy transformed their production operations and industrial automation environment using EOT’s industrial data ops platform.

25

+Years data experience

120

+Project Delivered

500

+Models built Daily

150

+projects Committed