- marketing admin

- Articles

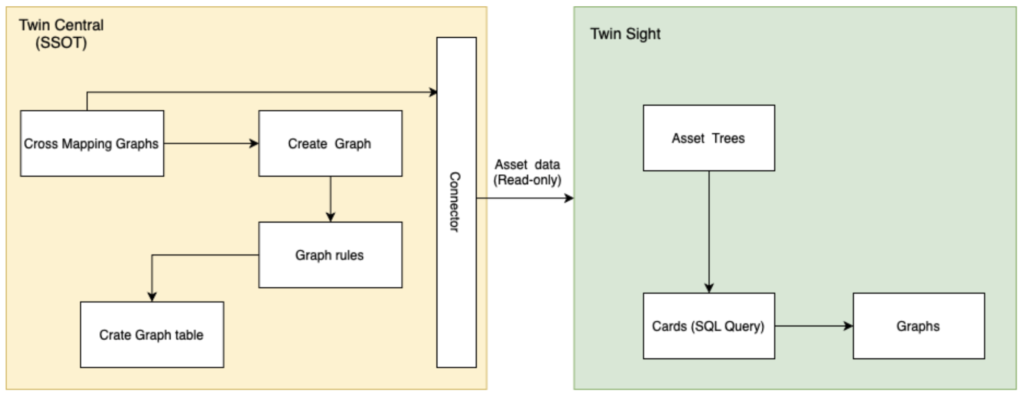

Twin Central is a simple GUI-based Data Integration platform capable of retrieving data from different data sources to make it available for either data visualization or aggregation. It is customized to handle data retrieval requests from the industrial data lakes, aggregate data, and use it for various data visualization pipelines.

Industrial Digital Twin

Building a reliable and close-to-real replica of the industrial assets is necessary for maintaining a fail-safe production environment. Using the concept of Digital Twin, it is possible to create a perfect copy of the industrial devices using the retrieved and organized data ingestion from these assets through various industrial data lakes or Cloud Historians.

Twin Central is the new Digital Twin for Industrial IoT to park and manage industrial assets from a Unified Interface. With the presence of Twin Central, industrial assets availability is assured 24/7 as it synchronizes in real-time for instantaneous data aggregating purposes.

User interaction

As part of the aggregation of data assets from different data sources using Twin Central, the retrieved data is in two groups,

- Semantic data

- Time series data

Semantic data is the meta-data collected from industrial data assets, identified using asset tags names or nodes, and pushed into the visualization pipeline. Twin Central uses the time series data from SCADA systems and builds asset maps.

Time series data can be static values or collected from real-time data feeds routed into the Twin Central application using the data migration platform called Twin Talk.

Twin Central features

Data ingested from different sources flows inside Twin Central to serve as a bridge for sharing data for Twin Sight, the data visualization platform. It acts as a backup for industrial assets since it holds the state information of all industrial asset nodes in real time. The Twin Central benefits and its possible use cases are detailed below.

Data Strategy

To manage, operate and resolve data exchanges from different industrial data lakes, maintaining a central data repository that acts as a perfect replica of physical device nodes present in the Operational network of the Industrial IoT.

Data aggregated from Industrial Data Lakes needs appropriate conditioning before extracting valuable insight from further data analytics. Using an achievable data ingest strategy from operational networks (on the field) to the applications inside the enterprise networks.

A typical data strategy is to adopt and build a custom Digital Twin that holds the time series data of physical assets in a node hierarchy structure. Using the virtual copies of physical assets, create a reliable Single Source of Truth (SSOT), which caters to the data requests for data analytics and visualization workflows.

Cloud Historian

Data Historians inside Operational Network are restricted from access by external systems or even from enterprise network devices. This disconnect between the Data Historian and the devices or applications running in the enterprise network reduces data availability for real-time visualization applications.

As a real-time industrial data aggression platform, Twin Central serves the data needs of Enterprise network applications or devices by creating a reliable replica of the actual industrial assets in real time. It turns traditional Data Historians into Cloud Historians without disturbing the integrity of Operational networks.

Relationship graphs

Twin Central serves as the primary SSOT for Twin Sight visualization workflows. The core of Twin Central is to map industrial data assets, using a tag name (or nodes), between a base graph and an extended graph.

The relationship graph matches asset nodes in the base graph to the node in the extended graph. The node names must match each other, irrespective of the node hierarchy, which Twin Central uses to map two assets and build a new asset graph with these updated graph values.