Customer Case Study

How a Global Energy Company Unified Industrial Data to Enable Real-Time Decisions and Scalable AI/ML with AWS and EOT.AI

Customer Overview

As one of the world’s largest integrated energy companies — and operator of some of the most productive well pads in the U.S. — this organization embarked on a bold digital transformation initiative. Their primary goals were to improve operational efficiency, increase access to data, and enable real-time decision-making.

To achieve this, they leveraged AWS’s suite of energy industry solutions and partnered with EOT.AI. Together, they set out to modernize production operations, reduce costs, and improve safety — all while laying a foundation for enterprise-scale industrial intelligence enabling machine learning (ML) at its core.

key challenges

Like many in the industrial sector, the customer faced a familiar set of challenges that had been limiting operational agility and innovation:

Data Silos: Disconnected systems and tools across assets and regions limited the company’s ability to generate a unified view of operations.

Delayed Access to Insights: The company relied heavily on a traditional data warehouse architecture that lacked real-time responsiveness. As a result, business reports were often delayed — forcing operational teams to make decisions without access to current performance data.

Low Granularity and Fidelity: The existing infrastructure couldn’t support the high-resolution data needed to power advanced analytics and machine learning.

Scalability of AI/ML: Although the customer was eager to deploy machine learning at scale — particularly for use cases like wellhead pressure anomaly detection — limitations in data architecture and access capabilities posed a serious barrier.

Recognizing these challenges, the company saw a critical opportunity: to consolidate data sources, democratize access to high-fidelity information, and enable near real-time visibility and intelligence across the business.

The solution

To overcome these challenges, and to lay the groundwork for scalable AI and real-time analytics, the customer deployed a cloud-native industrial data platform anchored in AWS and powered by EOT’s industrial data delivery platform.

How EOT.AI’s Twin Talk Powered Real-Time Data Transformation

EOT.AI’s Twin Talk played a pivotal role in the company’s transformation. Twin Talk securely extracted raw data from SCADA systems, enriched it with contextual metadata (like asset hierarchies and engineering units), and then streamed that data in near real-time to AWS services. As a result, this architecture ensured that both IT and OT data were made available to stakeholders with enterprise-grade granularity, fidelity, and availability.

Results & Business Impact

The results were transformative — not just from a technical standpoint, but also from an operational and cultural perspective:

Real-Time Operational Intelligence

ML-Ready Data Infrastructure

Significant Cost Reduction

By transitioning from a legacy data warehouse model to cloud-native infrastructure, the customer achieved a 45% reduction in IT/OT total cost of ownership, while improving performance and scalability.

Enterprise Data Unification

Twin Talk enabled the customer to consolidate siloed data into a single model across 14 states — processing over 1 billion data points per day. This unified approach supports cross-site analytics, benchmarking, and enterprise KPIs supporting more than 300+ use cases (applications) to date.

Improved Governance and Safety

Centralizing their industrial data platform also helped enhance data quality and standardization, enabling stronger access controls — supporting the customer’s safety and compliance goals.

conclusion

This transformation — driven by close collaboration between AWS and EOT.AI — clearly demonstrates how cloud-native architectures and modern industrial data platforms can unlock real-time intelligence and scalable AI across energy operations.

By democratizing data access, breaking down silos, enabling real-time intelligence, and building the infrastructure to deploy ML at scale, the customer has positioned itself as a leader in data-driven operations. The blueprint they’ve created — with EOT.AI as a foundational layer — is one that many other industrial organizations are now looking to replicate.

About TWIN FUSION

Twin Fusion is an Operational Innovation Platform designed to empower industrial enterprises. It seamlessly integrates data from OT systems (SCADA, historians) with IT platforms like Databricks and Snowflake.

Twin Fusion enables operational IT teams to create scalable solutions that bridge the gap between operations and business strategy. Solutions like real-time dashboards, predictive maintenance tools, or optimization apps.

Twin Fusion transforms operational complexity into actionable insights, driving productivity, efficiency, and enterprise-wide collaboration.

ready to unlock the full potential of your operational data?

Discover how EOT’s Twin Fusion product suite can accelerate your digital transformation.You can find Twin Talk and the EOT Twin Fusion Product suite on the aws Marketplace 👉 Click Here

Learn More About twin fusion

twin sight - intuitive data visualization

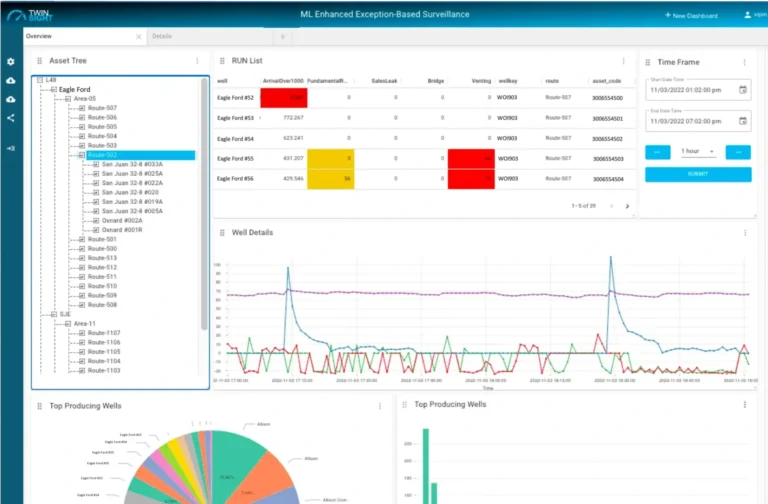

EOT Twin Sight supports the visualization and reporting of large-scale analytics and deployment of machine learning (ML) models. The ML model results are embedded in the use-case driven modern, low-code, AI-powered visualization platform, enabling operational users to make data-supported decisions that drive operational efficiency across their enterprise.

Twin Central - Industrial knowledge graph

EOT Twin Central, a new class of industrial data operation software, when combined with EOT Twin Talk and Twin Sight, empowers organizations to achieve both quality and speed by enabling development teams who best understand the solution context to act directly on the data, its quality, and governance, without resorting to costly centralized master data management. EOT Twin Central facilitates the creation of an asset-centric, single source of truth semantic data model.

Twin Talk - data ingestion and curation

EOT’s Twin Talk serves as a Data Integration Platform for industrial IoT, bridging the gap between operational systems (OT) and cloud (IT) solutions. It removes the barriers associated with complex, firewalled networks and IT infrastructures, providing secure, scalable access to operational data. Twin Talk empowers digital transformation executives, operators, data scientists, and business analysts to leverage AI, machine learning, and analytics tools for real-time insights and operational intelligence. This platform simplifies the transmission of sensor data from operational assets, allowing companies to focus on delivering productivity through digitization.