Customer Case Study

Revolutionizing Offshore Drilling

How a Leading Energy Company Unlocked OT Data for Real-Time Machine Learning Insights with EOT’s Twin Talk Solution

Customer Overview

A leading multinational energy services company needed a real-time monitoring and analytics solution to improve the performance and reliability of its offshore drilling platforms. By enhancing operational visibility and leveraging advanced machine learning, the company aimed to minimize downtime, optimize asset performance, and maximize profitability.

the challenge

The company’s operations team lacked real-time access to critical drilling data, making it difficult to detect anomalies and prevent potential downtime or production disruptions. Existing systems provided delayed insights, limiting the ability to respond proactively to operational issues.

Without up-to-the-second data, the company risked costly unplanned downtime, safety hazards, and inefficiencies across its offshore assets. To address this, the company sought a high-performance, scalable data platform capable of ingesting and analyzing massive volumes of real-time data.

Solution: Twin Talk for Real-Time Data Aggregation & Analytics

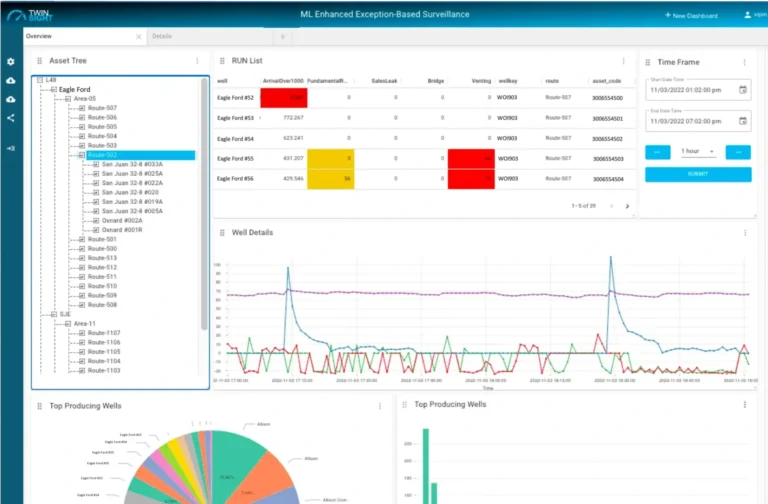

The company deployed EOT’s Twin Talk to handle the ingestion, aggregation, and visualization of operational drilling data from offshore wells. The solution enabled high-speed, high-volume data processing while maintaining security, efficiency, and scalability.

the implementation included:

Processing 1.4 billion data points per day from offshore wells

Sub-second latency for real-time visibility

Direct integration with AWS S3 for scalable storage

Databricks for machine learning training and anomaly detection to predict potential failures

Results & Business Impact

The successful deployment of Twin Talk delivered significant business value:

Real-Time Monitoring & Visibility: The operations team gained instant access to drilling data, allowing for proactive decision-making.

Increased Asset Performance: Improved visibility enabled optimized drilling operations, reducing failures and maximizing uptime.

Enhanced Company Profitability: Preventing unplanned downtime translated to millions in potential savings.

Lower Total Cost of Ownership (TCO): Outperformed previously deployed custom-coded solutions, while offering greater security and operational efficiency.

Lessons Learned

- Industrial projects can be accelerated using EOT’s Twin Talk to connect, enrich, and contextualize the exchange of data between OT and IT systems.

High-volume, low-latency data challenges with sub-second delivery requirements can be efficiently handled with Twin Talk, making it a scalable solution for industrial IoT applications.

Twin Talk can be deployed quickly through software configuration rather than requiring highly skilled engineers to develop extensive custom code.

conclusion

By leveraging EOT’s Twin Talk, the multinational energy company transformed its drilling operations, achieving real-time insights, improved asset performance, and reduced downtime. The solution’s scalability and security positioned the company for future growth and efficiency gains, making it a model for modern industrial IoT transformations.

About Twin Talk

Twin Talk offers a simple, secure, and scalable solution for delivering operational data from SCADA systems and historians to the cloud. Twin Talk revolutionizes the way industrial companies handle data. The platform enables cloud-based, event-driven, real-time architectures such as data lakes, mobile monitoring, and surveillance apps. The top benefit customers report is being able to quickly generate valuable insights from analytics, AI, and machine learning with Twin Talk.

Ready to Unlock the Full Potential of your Operational Data?

Sign up to schedule a time to learn how EOT’s Twin Fusion product suite can accelerate your industrial digital transformation.

You can find Twin Talk and the EOT Twin Fusion Product suite on the aws Marketplace 👉 Click Here

Learn More About twin fusion

twin sight - intuitive data visualization

EOT Twin Sight supports the visualization and reporting of large-scale analytics and deployment of machine learning (ML) models. The ML model results are embedded in the use-case driven modern, low-code, AI-powered visualization platform, enabling operational users to make data-supported decisions that drive operational efficiency across their enterprise.

Twin Central - Industrial knowledge graph

EOT Twin Central, a new class of industrial data operation software, when combined with EOT Twin Talk and Twin Sight, empowers organizations to achieve both quality and speed by enabling development teams who best understand the solution context to act directly on the data, its quality, and governance, without resorting to costly centralized master data management. EOT Twin Central facilitates the creation of an asset-centric, single source of truth semantic data model.

Twin Talk - data ingestion and curation

EOT’s Twin Talk serves as a Data Integration Platform for industrial IoT, bridging the gap between operational systems (OT) and cloud (IT) solutions. It removes the barriers associated with complex, firewalled networks and IT infrastructures, providing secure, scalable access to operational data. Twin Talk empowers digital transformation executives, operators, data scientists, and business analysts to leverage AI, machine learning, and analytics tools for real-time insights and operational intelligence. This platform simplifies the transmission of sensor data from operational assets, allowing companies to focus on delivering productivity through digitization.